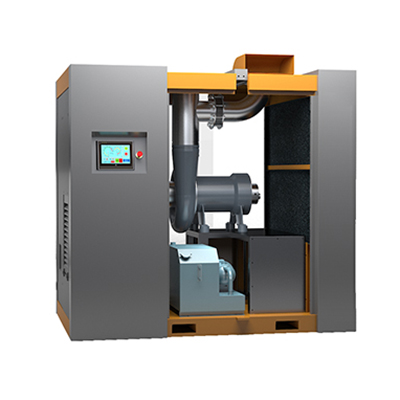

Air Suspension Bearing Centrifugal Blower

UCTB Series

- Industries: Sewage Treatment Textile Food & Beverage Medical Transportation Petrochemical Industry Packaging Paper & Printing Pharmaceutical Power Industry

Description

United air suspension centrifugal blower consists of air bearing with direct coupling technology, impeller, high-speed motor, no additional friction. The transmission gearbox and lubrication system removed and no more mechanical contact. Blower automatically adjusts the motor power consumption according to the output air volume (adjustable range 40-100%) to maintain the efficiency of equipment operation. Use speed control to adjust the motor speed, sustaining high efficiency within the scope of the workflow of the Blower.

Air Suspension Centrifugal blower, mostly used in industrial gas, municipal sewage treatment and other fields. Such pipeline gas, pressure transport, cement plant, petrochemical industry, Food and Pharmaceutical Fermentation, power plant desulfurization oxidation, electronic machinery, metallurgy, building materials, textiles printing and dyeing, agriculture and food drying.

• Energy conservation and efficient

• No maintenance, no lubricating oil, no mechanical maintenance

• Low noise, low vibration

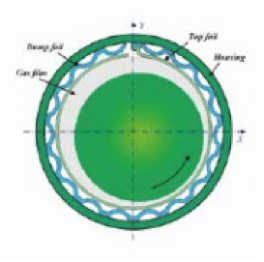

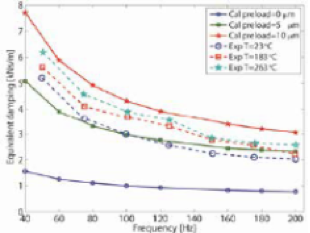

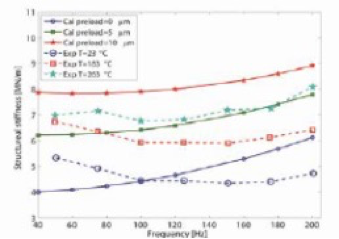

Air Suspension Bearing Technology

• Self-developed patent winning core technology.

• Ultra-high-speed air bearing ensures true oil-free and no mechanical friction.

• The air bearing has tested 20,000 times of start and stop, the approval service life of semi-permanent.

Ultra-High-Speed Permanent Magnet Motor Technology

• The efficiency of Permanent magnet synchronous motor (PMSM) is over 97%.

• The high-speed PMSM directly coupled to transmission and power efficiency is 98%.

• Unique air duct design enhancing the cooling effect on PMSM.

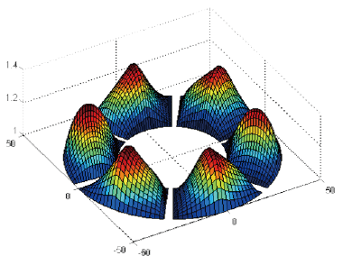

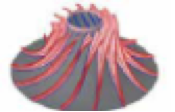

Aero-Alloy Impeller

• High-strength and high precision aviation aluminium alloy.

• Ternary flow impeller, five-axis high-speed machine milling, passed 115% Overspeed test.

• Flow regulation between 40% and 105%, high efficiency, good flow performance.

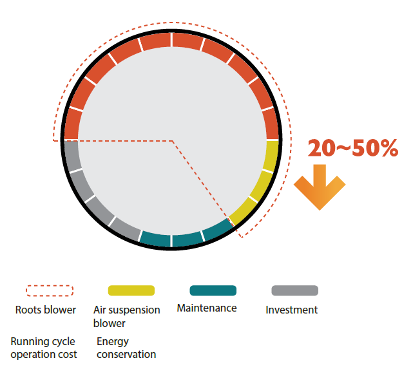

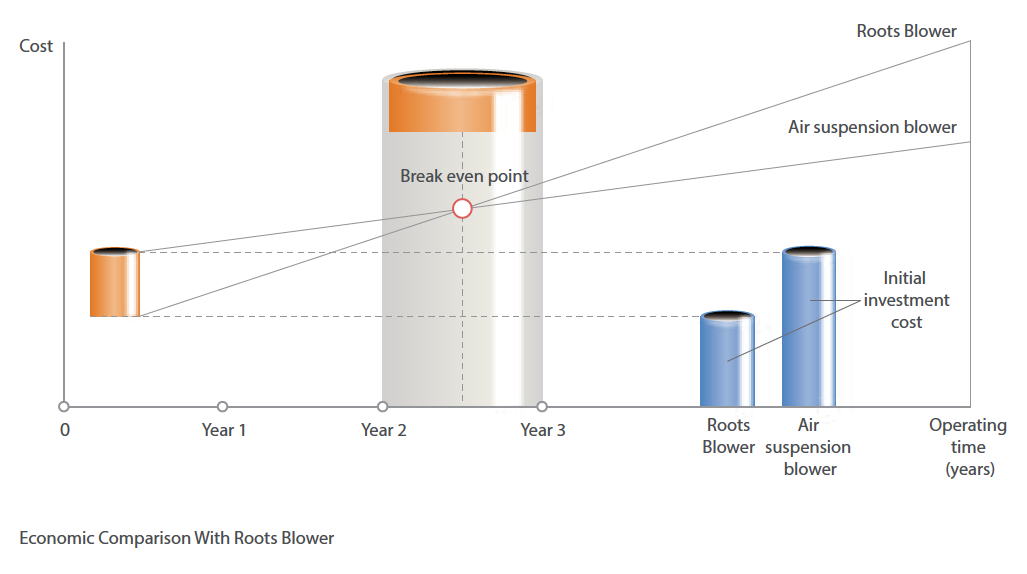

The Energy Saving Ratio Between 20%~50%

Compared with traditional blowers, air-suspended blowers dramatically reduce operating costs to ensure customer profitability. Its superior energy-saving technology helps customer recover the investment cost in 2~3 years.

• VFD speed regulation technology;

• Accurately adjust the motor rotation according to the required air volume;

• Energy-saving up to 20%~50%;

• Focus on reducing energy consumption and minimizing customer investment costs.

Technical Parameters

AIR SUSPENSION BEARING CENTRIFUGAL BLOWER UCTB SERIES | |||||||||

Rated power (kw) | 55 | 75 | 90 | 132 | 160 | 200 | 300 | 400 | |

UCTB SERIES | Pressure rise (kPa) | Flow (m³/min) | |||||||

40 | 66 | 90 | 118 | 175 | 210 | 235 | 288 | 390 | |

60 | 46 | 64 | 100 | 130 | 145 | 162 | 246 | 330 | |

80 | 36 | 51 | 83 | 90 | 109 | 130 | 185 | 255 | |

100 | 52 | 75 | 87 | 110 | 150 | 200 | |||

120 | 72 | 100 | 130 | 130 | |||||

150 | 80 | 110 | 110 | ||||||

REMARKS: | |||||||||

WORKING CONDITION: 20℃,1.033KGF/C㎡,65%RH | |||||||||

ERROR RANGE: +/- 5% | |||||||||

ACCORDING TO THE ACTUAL CONDITIONS, THE ABOVE DATA ARE SUBJECT TO CHANGE WITHOUT PRIOR NOTICE AND CAN COMMUNICATE WITH THE MANUFACTURER FOR CONSULTATION. | |||||||||

Share:

Related Product

Magnetic Suspension High-Speed Turbo Blower

UCMB Series

Oil Free Screw Blower

UCBS Series

Air Suspension Bearing Centrifugal Blower

UCTB Series