Low Pressure VFD Speed Regulation Permanent Magnet Screw Air Compressor

UC-VPM Series

| Working Pressure | 2 - 4 [bar] | 29 - 58 [psig] |

| Free Air Delivery | 459 - 2154 [m3/min] | 13 - 61 [cfm] |

| Working Power | 37 - 220 [kw] | 50 - 295 [hp] |

- Industries: Sewage Treatment Textile Food & Beverage Medical Transportation Petrochemical Industry Packaging Paper & Printing Pharmaceutical Power Industry

Description

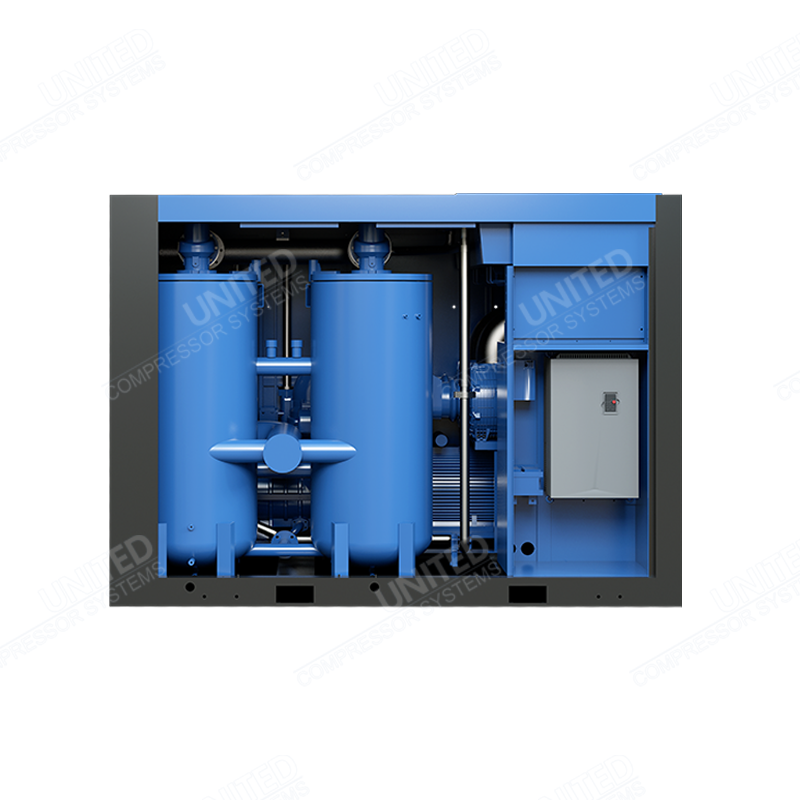

United low-pressure series screw air compressor is a new type of compressor developed in response to the demand for energy saving, emission reduction and environmental protection. It changes the circumstances using the traditional high-pressure compressor to decompress the compressed air and then transmit to the air equipment, which saves energy.

At present, the lowest exhaust pressure of United in the screw air compressor industry can reach 1.2bar and ensure that the exhaust oil content is less than 2ppm, which means clean and stable air supply. Enclosed cabinet low noise design is more environmentally friendly than a piston compressor. Given the situation of many industries requiring no downtime can ensure the maintenance during continuous operation; Fault alarm configurated to make full emergency preparation for users, stable and reliable operation.

Advantages and Characteristics:

· Can save more than 30% of the electricity;

· The low-pressure air end can automatically adjust the internal compression ratio according to the service pressure and maintain the best energy efficiency within the exhaust pressure range of 2-5bar;

· In many industries, such as chemical, glass, petroleum, textile, printing, dyeing, and ceramics, the required working pressure of compressed air is only 3-5bar. However, at present, these industries usually use 7-10bar air compressors coupling with a pressure reducing valve to achieve low pressure; it is undoubtedly a considerable waste of energy. For this reason, UNITED has developed low-pressure screw air compressor which directly outputs the low-pressure compressed air required by these industries; the compressor uses less energy to meet the production requirement, and user's production cost will significantly improve.

Mechanic System

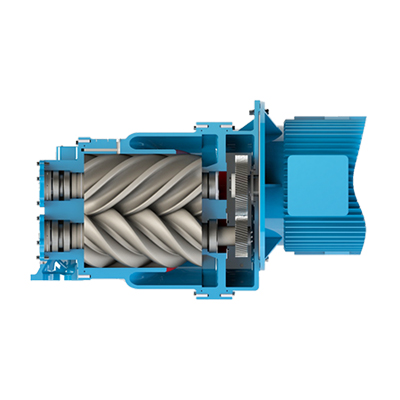

Self-Developed Special Air End

· International leading moulded lining, 4:6 tooth ratio, less tooth and more air suction;

· Large rotor, low speed, and long life;

· The inner oil circuit of the air end can precisely control the amount of oil injection, helping the lubrication and cooling reach the best performance;

· SKF bearings adapted to the load changing, which is flexible, efficient, proven long durability, and it guarantees the life of the air end.

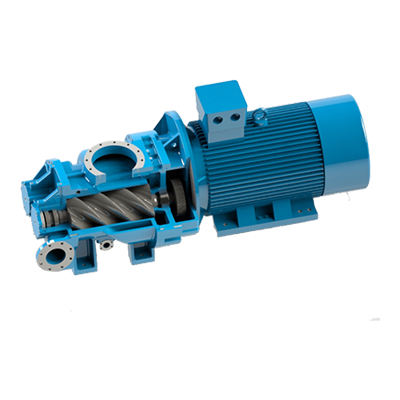

Low-Pressure Screw Air End Drive Chain

· The high-efficient driving motor directly connected to the two-stage compression air end without coupling, the transmission chain is maintenance-free, reducing energy consumption by 1%;

· IP55 fully closed motor and air end housing integrated, effectively prevents metal particles, dust, moisture and other pollutants infiltrating into the motor and air end, makes the compressor performance more stable;

· The motor bearing uses strengthened cylinder + ball bearing, delivering higher strength and reliability;

· The machining accuracy of transmission gear up to aviation level 6, multi-channel heat treatment and related processing technology ensure the superior surface hardness, ultra-high wear resistance and yield strength of all mechanical components;

· Independent oil supply system and precise oil filtration effectively ensure the stability and reliability of the entire transmission under the long-time operation of full load.

Intake and Filtration Systems

Prefilter Protective Layer:

Prevent large particles of dust, cotton and other sundries from entering the air compressor. Keep the compressor internal clean. Strictly observe the first pass of compressed air.

High-Efficiency Particulate Air (HEPA) Filtration:

Heavy-duty air filtration system powered by Donaldson USA, with filtration accuracy up to 99.9% for particles greater than 3μm. Suitable for all kinds of heavy dust environments.

Double Large Diameter Intake Assembly Design:

The pressure difference of all air path less than 0.2bar, greatly extending the service life of the air filtration system.

Optimized Design of Large Diameter Air Inlet Valve:

Low energy consumption in no-load operation, cast aluminium material, more stable performance.

The optimized mould design of the intake pipe:

High strength rubber sealing, firm and durable.

Oil Filter:

Donaldson oil filters, high grade of clean filtration, effectively protect the safe operation of the air end bearing, extend the service life of the air end.

Oil and Air Separation System:

Euro design efficient oil and air separation core, glass fibre filter material, long life, more efficient, no need for frequent replacement. The aggregate separation core and the oil return device work together, recover and recycle the lubricating oil effectively, avoiding oil over-spraying, and ensuring the oil content of the compressor exhaust ≤2ppm.

Lubricating Oil:

United lubricating oil has good oxidation resistance, high-temperature resistance, high flash point, excellent thermal conductivity and many other characteristics.

Cooling System

· The design allowance of heat exchange is 20%-50%, which ensures the stable operation of the compressor in an extreme environment and minimize pressure drop.

· Standard motor frequency conversion, accurate oil temperature control; further reduce air compressor energy consumption.

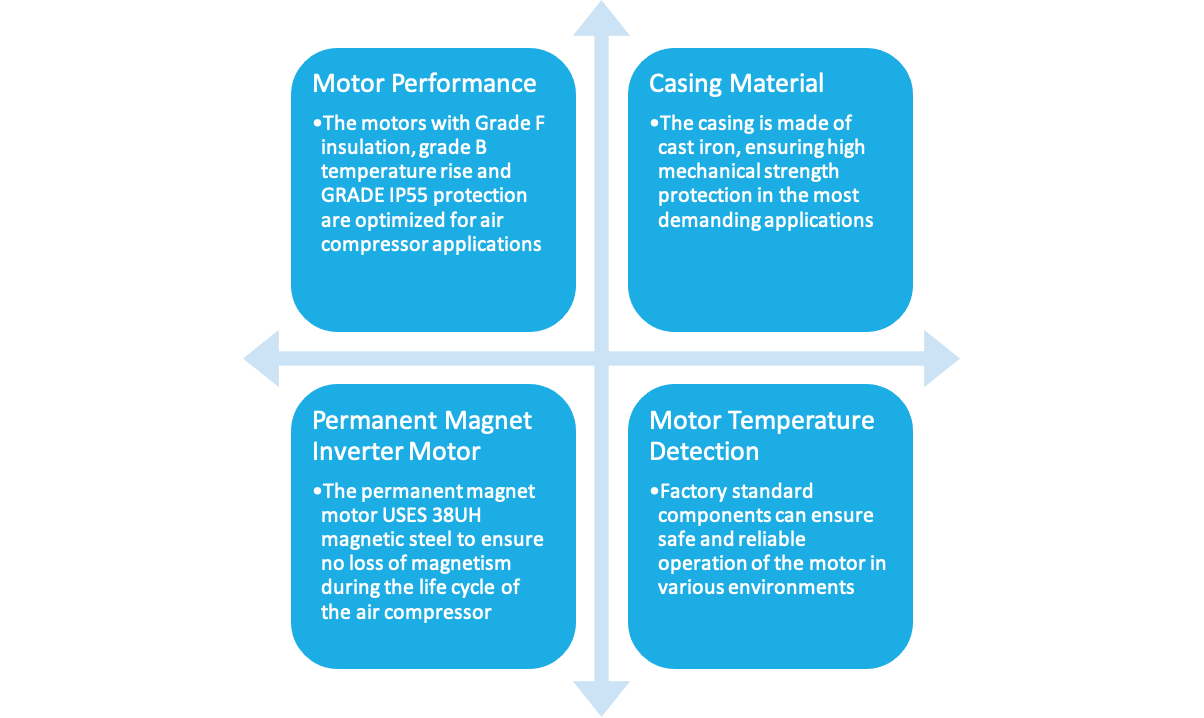

Features of Permanent Magnet Synchronous Motor (PMSM)

· The motor efficiency is as high as 96%, and the power factor is 0.98, far exceeding the level 1 energy efficiency standard;

· Permanent magnet with high coerce and high-temperature resistance ensures no demagnetization at a high temperature of 180°C;

· Independent fan cooling, to ensure the motor safe running under long hours and low frequency;

· F grade insulation, 70K temperature rise design, suits the high-temperature working condition of air compressor;

· Fully enclosed IP55 protection protects the clean internal environment of the motor and extends the life of permanent magnet and insulation;

· Built-in temperature protection protects winding insulation and permanent magnet.

Permanent Magnet Synchronous Motor Vs Ordinary Asynchronous Motor

High efficiency:

The excitation system loss eliminated, improving efficiency.

Keep high-efficient at low-load state:

The energy efficiency of the PMSM is more than 9% higher than the asynchronous motor and remains unchanged with the reduced frequency.

Large starting torque:

The maximum starting torque of the PMSM may up to 3 times higher than the rated torque, while the general asynchronous motor has 1.6 times only.

More stable control:

The PMSM response time less than 50ms. The air production volume may be adjusted transiently within a broad range to stabilize air pressure precisely.

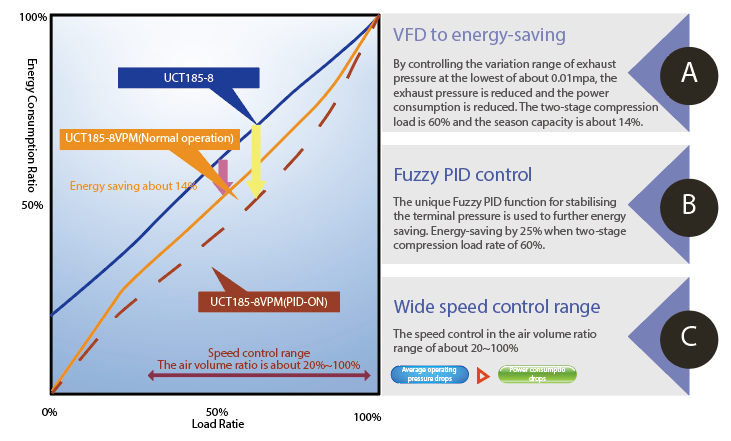

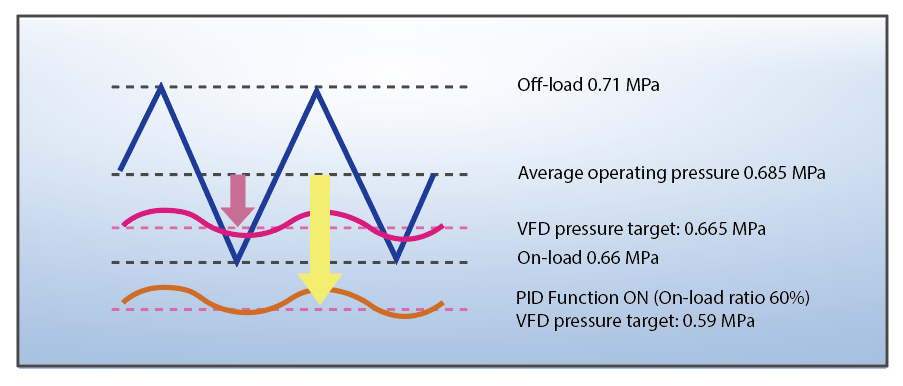

Features of United VFD Speed Regulation PMSM Air Compressor

· Ultra-low temperature rise design, to allow compressor long-term low-frequency stable operation;

· Adopting the open-loop vector control system, it controls faster, and the speed regulation is more accurate;

· When the frequency is reduced by more than 50%, the compressor unit can still operate efficiently;

· Stable pressure accurately controls pressure fluctuation within 0.01mpa; With soft-start characteristic, avoid start current shock, reduce start energy consumption.

Electric System

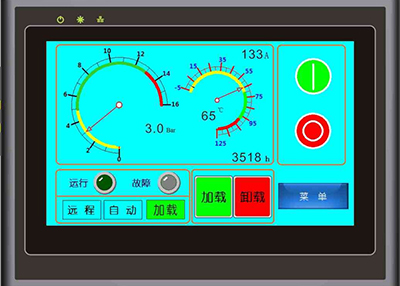

New Generation of Intelligent Controller | Internet of Things Module | High-Quality Electrical Components |

PLC + touch screen; Friendly user interface; Full-time monitoring operation status; Intelligent operation; USB, COM interface, with upgradable function.

|

Remote monitoring the operation and maintenance; Remote operation, Data collection, Energy-saving management.

|

SIEMENS electronic components; variety selection; Applicable to all climatic conditions.

|

Modular Vector Frequency Drive (VFD)

Large redundant heat design, more stable operation and longer equipment life under severe service environment;

No stop at an instantaneous stop, over-excitation protection and many other excellent functions to deal with various emergencies;

Built-in PLC and a variety of communication interfaces, more convenient to use and maintain;

Wide range of speed regulation, high accuracy of speed stability, deliver stable operation with on-load at an ultra-low speed of 0.01Hz.

Technical Parameters

United Low-Pressure VFD SPeed Regulation Permanent Magnet Screw Air Compressor | |||||||||

MODEL | Working Power (KW) | Working Power (HP) | Working Pressure (bar) | Working Pressure (psig) | Free Air Delivery (CFM) | Free Air Delivery (m³/min) | Dimensions of Exhaust Outlet | Weight (KG) | Profile Dimensions(L×W×HMM) |

UC37-2VPM | 37 | 50 | 2 | 29 | 494 | 14 | DN125 | 2400 | 2600*1460*2080 |

UC37-3VPM | 3 | 44 | 459 | 13 | DN100 | 2400 | 2600*1460*2080 | ||

UC45-2VPM | 45 | 60 | 2 | 29 | 600 | 17 | DN125 | 2600 | 2600*1460*2080 |

UC45-3VPM | 3 | 44 | 494 | 14 | DN125 | 2400 | |||

UC55-2VPM | 55 | 74 | 2 | 29 | 759 | 21.5 | DN150 | 4000 | 3200*1850*2150 |

UC55-3VPM | 3 | 44 | 600 | 17 | DN125 | 2800 | 2600*1460*2080 | ||

UC55-4VPM | 4 | 58 | 494 | 14 | DN100 | 2600 | 2600*1460*2080 | ||

UC75-2VPM | 75 | 101 | 2 | 29 | 953 | 27 | DN150 | 4000 | 3200*1850*2150 |

UC75-3VPM | 3 | 44 | 759 | 21.5 | DN125 | 2800 | 2600*1460*2080 | ||

UC75-4VPM | 4 | 58 | 671 | 19 | DN100 | 2600 | 2600*1460*2080 | ||

UC90-2VPM | 90 | 121 | 2 | 29 | 1130 | 32 | DN200 | 4200 | 3400*2150*2300 |

UC90-3VPM | 3 | 44 | 953 | 27 | DN150 | 4000 | 3200*1850*2150 | ||

UC90-4VPM | 4 | 58 | 830 | 23.5 | DN100 | 2800 | 2600*1460*2080 | ||

UC110-2VPM | 110 | 148 | 2 | 29 | 1413 | 40 | DN250 | 5800 | 4200*2150*2300 |

UC110-3VPM | 3 | 44 | 1130 | 32 | DN150 | 4200 | 3400*2150*2300 | ||

UC110-4VPM | 4 | 58 | 1024 | 29 | DN125 | 3600 | 3200*1950*2120 | ||

UC132-2VPM | 132 | 177 | 2 | 29 | 1660 | 47 | DN300 | 6900 | 4200*2150*2300 |

UC132-3VPM | 3 | 44 | 1413 | 40 | DN250 | 5800 | 4200*2150*2300 | ||

UC132-4VPM | 4 | 58 | 1165 | 33 | DN150 | 3900 | 3200*1950*2120 | ||

UC160-2VPM | 160 | 215 | 2 | 29 | 1967 | 55.7 | DN300 | 7000 | 4400*2150*2300 |

UC160-3VPM | 3 | 44 | 1660 | 47 | DN250 | 6900 | 4200*2150*2300 | ||

UC160-4VPM | 4 | 58 | 1413 | 40 | DN200 | 4500 | 3400*2150*2300 | ||

UC185-4VPM | 185 | 248 | 4 | 58 | 1660 | 47 | DN200 | 5000 | 3400*2150*2300 |

UC200-3VPM | 200 | 268 | 3 | 44 | 1967 | 55.7 | DN250 | 7100 | 4400*2150*2300 |

UC220-3VPM | 220 | 295 | 3 | 44 | 2154 | 61 | DN250 | 7200 | 4400*2150*2300 |

REMARKS: | |||||||||

1. A - FAN COOLING; W - WATER COOLING. | |||||||||

2. THE FAD REFERS TO A VALUE IN WHICH THE UNIT IS TESTED FOLLOWING ISO1217 (GB/T3853) UNDER THE LOAD CONDITIONS. | |||||||||

3. THE NOISE LEVEL CONFORMS TO ISO 2151 AND 9614-2 AT FULL OPERATIONAL PRESSURE AND SPEED; NOISE TOLERANCE ± 3 DB(A). | |||||||||