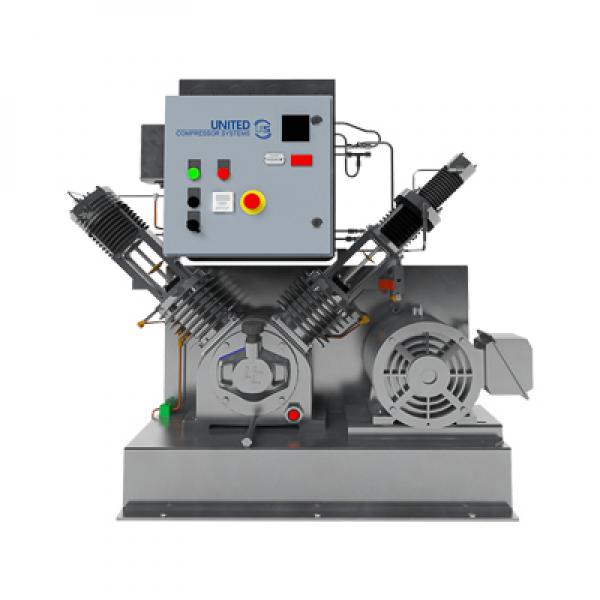

Oil Free Scroll Air Compressor

UCW Series

| Working Pressure | 8-10 [bar] | 116-145 [psig] |

| Free Air Delivery | 0.2-3.6 [m3/min] | 7-127 [cfm] |

| Working Power | 2.2-33 [kw] | 3-44 [hp] |

- Industries: Sewage Treatment Textile Food & Beverage Medical Transportation Petrochemical Industry Packaging Paper & Printing Pharmaceutical Power Industry

Description

The static vortex disk and the moving vortex disk of the oil-free scroll air compressor move in a plane with a small radius under a particular phase. The moving vortex disk and the static vortex disk mesh to form several closed crescent-shaped compression cavities. The air inhaled into the working chamber is gradually compressed by the subsequent crescent-shaped compression chamber, and then discharged from the outlet at the centre of the static vortex disk. The oil-free scroll compressor produces oil-free compressed air that widely used in the fields of food, medicine, electronics, printing, chemical industry, precision spraying and others.

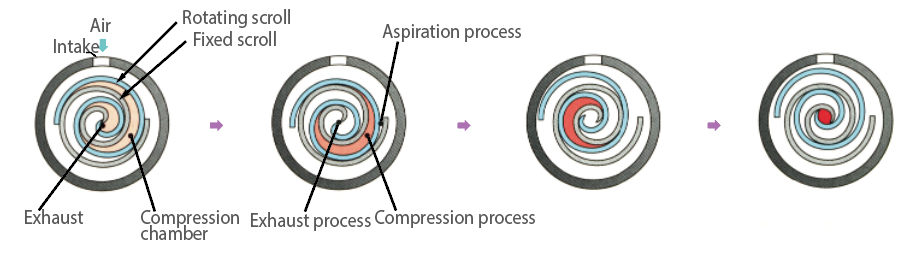

The Working Principle of Scroll Compressor

· Air draws in through an inlet located on the outer side of the static vortex disk.

· The air enclosed in the compression chamber is compressed toward the centre by a chamber reduction driven by the rotational motion.

· The compression space is the smallest at the centre, and the highly compressed air is extruded outward through the vent at the centre.

· 1 - 3 (inhalation > compression > exhaust) motion action is repeated.

Reliable and Stable

· The vortex disc of the scroll compressor works at high temperature due to lack of lubricating oil during operation. The Neo involute tooth profile technology developed by Hitachi has well solved the problem of vortex disk thermal deformation at high temperature and virtually ensured the reliability of the scroll compressor.

· Bearings with High-reliability surface treatment.

Low Vibration and Low Noise

Optimized scroll compressor cabinet design by Hitachi, low noise close to the library environment. (3.7KW model, noise value is only 47dB[A])

Easy Maintenance

· Medium-term maintenance cycle extended to five years or 12500 hours from the original four years or 10000 hours.

* The maintenance cycle for the 1.0MPa pressure compressor is still four years or 10,000 hours.

· By adding oiling port, can fill up oil grease without removing the scroll disk of the scroll compressor. Simplify the maintenance process.

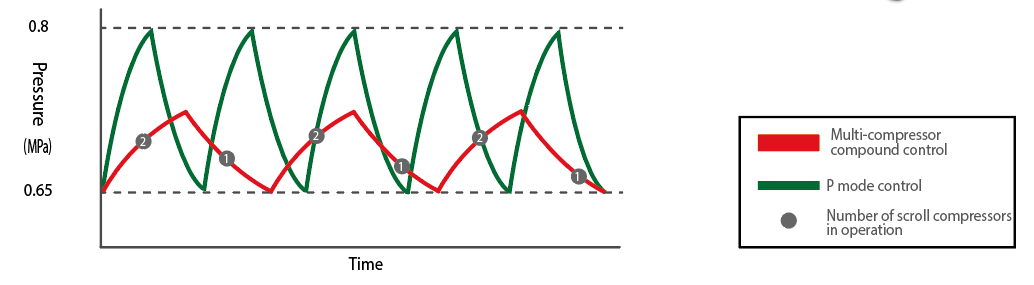

Energy Saving Under Multi-Compressor Compound Control

· Based on the P mode control, added multi-compressor compound control, which allows switching between two unites.

· Under the multi-compressor compound control mode, it automatically controls the number of compressors running according to the intake air consumption, the compressor operation simplifies while the required air pressure guaranteed.

P Mode Control

Same as the pressure switch mode, when the maximum pressure reached, the compressor stops running. When the resume pressure reached, the compressor starts again.

Multi-Compressor Compound Control

Compressor exhaust pressure automatically controlled around the required pressure (control pressure). Avoid power consumption for reaching the unnecessary maximum pressure, thus achieving energy-saving.

Function Behind

Several scroll compressors linked together if one of the units fails the rest still can guarantee the continuous air supply.

*The air exhaust will be smaller than the standard specification.

Optimized Cabinet Design

· Save installation area.

· Low vibration and low noise.

Technical Parameters

OIL-FREE SCROLL AIR COMPRESSOR UCW SERIES | ||||||||||

MODEL | Working Power (KW) | Working Power (HP) | Working Pressure(bar) | Working Pressure(PSIG) | Free Air Delivery (CFM) | Free Air Delivery (m³/min) | Scroll Qty | Dimensions of Exhaust Outlet | Profile Dimensions (L×W×HMM) | Weight (KG) |

UCW2.2-8 | 2.2 | 3 | 8 | 116 | 9 | 0.25 | 1 | G1/2 | 800*700*1250 | 240 |

UCW2.2-10 | 2.2 | 3 | 10 | 145 | 7 | 0.2 | 1 | G1/2 | 800*700*1250 | 240 |

UCW3.7-8 | 3.7 | 5 | 8 | 116 | 14 | 0.4 | 1 | G1/2 | 800*700*1250 | 270 |

UCW5.8-8 | 5.5 | 7 | 8 | 116 | 21 | 0.6 | 1 | G1/2 | 800*700*1250 | 300 |

UCW7.7-8 | 7.7 | 10 | 8 | 116 | 31 | 0.88 | 2 | Rp1 | 1350*850*1320 | 470 |

UCW7.7-10 | 7.7 | 10 | 10 | 145 | 25 | 0.7 | 2 | Rp1 | 1350*850*1320 | 470 |

UCW11-8 | 11 | 15 | 8 | 116 | 42 | 1.2 | 2 | Rp1 | 1350*850*1320 | 500 |

UCW11-10 | 11 | 15 | 10 | 145 | 35 | 1 | 2 | Rp1 | 1350*850*1320 | 500 |

UCW16.5-8 | 16.5 | 22 | 8 | 116 | 64 | 1.8 | 3 | Rp1 | 1350*850*1320 | 650 |

UCW16.5-10 | 16.5 | 22 | 10 | 145 | 53 | 1.5 | 3 | Rp1 | 1350*850*1320 | 650 |

UCW18.7-8 | 18.7 | 25 | 8 | 116 | 71 | 2 | 4 | Rp1-1/4 | 1450*1700*1780 | 800 |

UCW18.7-10 | 18.7 | 25 | 10 | 145 | 64 | 1.8 | 4 | Rp1-1/4 | 1450*1700*1780 | 800 |

UCW22-8 | 22 | 30 | 8 | 116 | 88 | 2.5 | 4 | Rp1-1/4 | 1450*1700*1780 | 800 |

UCW22-10 | 22 | 30 | 10 | 145 | 78 | 2.2 | 4 | Rp1-1/4 | 1450*1700*1780 | 800 |

UCW30-8 | 30 | 40 | 8 | 116 | 115 | 3.25 | 6 | Rp1-1/4 | 1450*1700*1780 | 900 |

UCW30-10 | 30 | 40 | 10 | 145 | 95 | 2.7 | 6 | Rp1-1/4 | 1450*1700*1780 | 900 |

UCW33-8 | 33 | 44 | 8 | 116 | 127 | 3.6 | 6 | Rp1-1/4 | 1450*1700*1780 | 900 |

UCW33-10 | 33 | 44 | 10 | 145 | 106 | 3 | 6 | Rp1-1/4 | 1450*1700*1780 | 900 |

REMARKS: | ||||||||||

1. THE FAD REFERS TO A VALUE IN WHICH THE UNIT IS TESTED FOLLOWING ISO1217 (GB/T3853) UNDER THE LOAD CONDITIONS. | ||||||||||

2. THE NOISE LEVEL CONFORMS TO ISO 2151 AND 9614-2 AT FULL OPERATIONAL PRESSURE AND SPEED; NOISE TOLERANCE ± 3 DB(A). | ||||||||||

Share:

Related Product

Oil Free Scroll Air Compressor

UCW Series

Oil Free VFD Speed Regulation Screw Air Compressor

UCL-VFD Series

Oil Free Fixed Speed Screw Air Compressor

UCL Series